Electric car

|

||

| Sustainable energy | ||

| Renewable energy | ||

| Anaerobic digestion | ||

| Hydroelectricity · Geothermal |

||

| Microgeneration · Solar |

||

| Tidal · Wave · Wind | ||

| Energy conservation | ||

| Cogeneration · Energy efficiency | ||

| Geothermal heat pump | ||

| Green building · Passive Solar | ||

| Sustainable transport | ||

| Plug-in hybrids · Electric vehicles | ||

|

||

An electric car is an automobile which is propelled by electric motor(s) which are entirely powered by electrochemical cells. Electric cars are usually powered by on-board battery packs, and as such are usually battery electric vehicles (BEVs), although some are powered by fuel cells.

Although electric cars often give good acceleration and have generally acceptable top speed, the lower specific energy of production batteries available in 2010 compared with fossil fuels means that electric cars have relatively low range between charges, and recharging can take significant lengths of time. For shorter range commuter type journeys, rather than long journeys, electric cars are practical forms of transportation and can be inexpensively recharged overnight. Longer range journey options are currently being pursued by installing battery swapping station infrastructure throughout several pilot cities such as Tokyo.[3]

Electric cars have the potential of significantly reducing city pollution by having zero tail pipe emissions.[4][5][6] Vehicle greenhouse gas savings depend on how the electricity is generated. With the current U.S. energy mix, using an electric car would result in a 30% reduction in carbon dioxide emissions.[7][8][9][10] Given the current energy mixes in other countries, it has been predicted that such emissions would decrease by 40% in the UK,[11] 19% in China,[12] and as little as 1% in Germany.[13][14]

Electric cars are expected to have a major impact in the auto industry[15][16] given advantages in city pollution, less dependence on oil, and expected rise in gasoline prices.[17][18][19]

Etymology

Electric cars are a variety of electric vehicle (EV); the term "electric vehicle" refers to any vehicle that uses electric motors for propulsion, while "electric car" generally refers to road-going automobiles powered by electricity. While an electric car's power source is not explicitly an on-board battery, electric cars with motors powered by other energy sources are generally referred to by a different name: an electric car powered by sunlight is a solar car, and an electric car powered by a gasoline generator is a form of hybrid car. Thus, an electric car that derives its power from an on-board battery pack is called a battery electric vehicle (BEV). Most often, the term "electric car" is used to refer to pure battery electric vehicles, such as the REVAi and GM EV1.

History

Electric cars enjoyed popularity between the mid-19th century and early 20th century, when electricity was among the preferred methods for automobile propulsion, providing a level of comfort and ease of operation that could not be achieved by the gasoline cars of the time. Advances in ICE technology soon rendered this advantage moot; the greater range of gasoline cars, quicker refueling times, and growing petroleum infrastructure, along with the mass production of gasoline vehicles by companies such as the Ford Motor Company, which reduced prices of gasoline cars to less than half that of equivalent electric cars, led to a decline in the use of electric propulsion, effectively removing it from important markets such as the United States by the 1930s. However, in recent years, increased concerns over the environmental impact of gasoline cars, along with reduced consumer ability to pay for fuel for gasoline cars, and the prospect of peak oil, has brought about renewed interest in electric cars, which are perceived to be more environmentally friendly and cheaper to maintain and run, despite high initial costs. Electric cars currently enjoy relative popularity in countries around the world, though they are notably absent from the roads of the United States, where electric cars briefly re-appeared in the late 90s as a response to changing government regulations.

1890s to 1900s: Early history

Before the pre-eminence of internal combustion engines, electric automobiles held many speed and distance records. Among the most notable of these records was the breaking of the 100 km/h (62 mph) speed barrier, by Camille Jenatzy on April 29, 1899 in his 'rocket-shaped' vehicle Jamais Contente, which reached a top speed of 105.88 km/h (65.79 mph). Before the 1920s, electric automobiles were competing with petroleum-fueled cars for urban use of a quality service car.[20]

In 1897, electric vehicles found their first commercial application in the U.S. as a fleet of electrical New York City taxis, built by the Electric Carriage and Wagon Company of Philadelphia. Electric cars were produced in the US by Anthony Electric, Baker, Columbia, Anderson, Edison , Studebaker, Riker, Milburn, and others during the early 20th century.

Despite their relatively slow speed, electric vehicles had a number of advantages over their early-1900s competitors. They did not have the vibration, smell, and noise associated with gasoline cars. They did not require gear changes, which for gasoline cars was the most difficult part of driving. Electric cars found popularity among well-heeled customers who used them as city cars, where their limited range proved to be even less of a disadvantage. The cars were also preferred because they did not require a manual effort to start, as did gasoline cars which featured a hand crank to start the engine. Electric cars were often marketed as suitable vehicles for women drivers due to this ease of operation.

In 1911, the New York Times stated that the electric car has long been recognized as "ideal" because it was cleaner, quieter and much more economical than gasoline-powered cars. Reporting this in 2010, the Washington Post commented that "the same unreliability of electric car batteries that flummoxed Thomas Edison persists today."[21]

Acceptance of electric cars was initially hampered by a lack of power infrastructure, but by 1912, many homes were wired for electricity, enabling a surge in the popularity of the cars. At the turn of the century, 40 percent of American automobiles were powered by steam, 38 percent by electricity, and 22 percent by gasoline. 33,842 electric cars were registered in the United States, and the United States of America became the country where electric cars had gained the most acceptance. Sales of electric cars peaked in 1912.

Proposed as early as 1896 in order to overcome the lack of recharging infrastructure, a exchangeable battery service was first put into practice by Hartford Electric Light Company for electric trucks. The vehicle owner purchased the vehicle from General Electric Company (GVC) without a battery and the electricity was purchased from Hartford Electric through an exchangeable battery. The owner paid a variable per-mile charge and a monthly service fee to cover maintenance and storage of the truck. The service was provided between 1910 to 1924 and during that period covered more than 6 million miles. Beginning in 1917 a similar service was operated in Chicago for owners of Milburn Light Electric cars who also could buy the vehicle without the batteries.[22]

1990s to present: Revival of mass interest

At the 1990 Los Angeles Auto Show, General Motors President Roger Smith unveiled the GM Impact electric concept car, along with the announcement that GM would build electric cars for sale to the public.

In the early 1990s, the California Air Resources Board (CARB), the government of California's "clean air agency", began a push for more fuel-efficient, lower-emissions vehicles, with the ultimate goal being a move to zero-emissions vehicles such as electric vehicles.

In 2000, Hybrid Technologies, later renamed Li-ion Motors, started manufacturing electric cars in Mooresville, North Carolina. California electric car maker Tesla Motors began development in 2004 on the Tesla Roadster, which was first delivered to customers in 2008. The Roadster remains the only highway-capable EV in serial production and available for sale today. Senior leaders at several large automakers, including Nissan and General Motors, have stated that the Roadster was a catalyst which demonstrated that there is pent-up consumer demand for more efficient vehicles. GM Vice Chairman Bob Lutz said in 2007 that the Tesla Roadster inspired him to push GM to develop the Chevrolet Volt, a plug-in hybrid sedan prototype that aims to reverse years of dwindling market share and massive financial losses for America's largest automaker.[23] In an August 2009 edition of The New Yorker, Lutz was quoted as saying, "All the geniuses here at General Motors kept saying lithium-ion technology is 10 years away, and Toyota agreed with us -- and boom, along comes Tesla. So I said, 'How come some tiny little California startup, run by guys who know nothing about the car business, can do this, and we can't?' That was the crowbar that helped break up the log jam."[24]

The Nissan LEAF, due to be launched in 2010,[25] is expected to be the first all electric, zero emission five door family hatchback to be produced for the mass market. Lithium-ion battery technology, smooth body shell and advanced regenerative braking give the LEAF performance comparable to an ICE, a range of around 160 km and the capability to reach 80% recharge levels in under 30 minutes.[26] In June 2009 BMW began field testing in the U.S. of its all-electric Mini E,[27] through the leasing of 500 cars to private users in Los Angeles and the New York/New Jersey area.[28][29] A similar field test was launched in the U.K. in December 2009 with a fleet of more than forty Mini E cars.[30]

Comparison with internal combustion engine vehicles

An important goal for electric vehicles is overcoming the disparity between their costs of development, production, and operation, with respect to those of equivalent internal combustion engine vehicles (ICEVs).

Running costs

"Fuel" cost comparison: the Tesla Roadster sport car's plug-to-wheel energy use is 280 W·h/mi. In Northern California, the local electric utility company PG&E says that "The E-9 rate is mandatory for those customers that are currently on a residential electric rate and who plan on refueling an EV on their premises."[31] Combining these two facts implies that driving a Tesla Roadster 40 miles (64 km) a day would use 11.2 kW·h of electricity costing between US$0.56 and US$3.18 depending on the time of day chosen for recharging.[31] For comparison, driving an internal combustion engine-powered car the same 40 miles (64 km), at a mileage of 25 mpg, would use 1.6 US gallons (6.1 l; 1.3 imp gal) of fuel and, at a cost of US$3 per gallon, would cost US$4.80.

Maintenance costs can be included in the comparison as well. Electric cars have expensive batteries that must be replaced but otherwise incur very low maintenance costs. The Tesla Roadster's very large battery pack is expected to last seven years with typical driving and costs US$12,000 when pre-purchased today.[32][33] Driving 40 miles (64 km) per day for seven years or 102,200 miles (164,500 km) leads to a battery consumption cost of US$0.1174 per 1 mile (1.6 km) or US$4.70 per 40 miles (64 km). The company Better Place provides another cost comparison as they anticipate meeting contractual obligations to deliver batteries as well as clean electricity to recharge the batteries at a total cost of US$0.08 per 1 mile (1.6 km) in 2010, US$0.04 per mile by 2015 and US$0.02 per mile by 2020.[34] 40 miles (64 km) of driving would initially cost US$3.20 and fall over time to US$0.80. The typical gasoline powered car can last 250,000 miles with some level of investment in maintenance. This cost comparison calculation for the electric car varies depending on the costs of gasoline and electricity, the mileages of the vehicles, the type of driving being considered, and the value to the owner of their fuel choice.

The Tesla Roadster uses about 17.4 kW·h/100 km (0.63 MJ/km; 0.280 kW·h/mi)[35], the EV1 used about 11 kW·h/100 km (0.40 MJ/km; 0.18 kW·h/mi).[36]

Nissan estimates the 5 year operating cost to US$1,800 and US$6,000 for a gasoline car.[37] The documentary film Who Killed the Electric Car?[38] shows a comparison between the parts that require replacement in a gasoline powered cars and EV1s, with the garages stating that they bring the electric cars in every 5,000 mi (8,000 km), rotate the tires, fill the windshield washer fluid and send them back out again. Even the hydraulic brakes require less maintenance because regenerative braking itself also slows the vehicle, as it does with a hybrid.

Range

"Range anxiety" is a reason that many automakers marketed EVs as "daily drivers" suitable for city trips and other short hauls.[39] The average American drives less than 40 miles (64 km) per day; so the GM EV1 would have been adequate for the daily driving needs of about 90% of U.S. consumers.[38]

The Tesla Roadster gets 200 miles (320 km) per charge; more than double that of prototypes and evaluation fleet cars currently on the roads.[40] On Oct. 27, 2009, the Roadster set a new world record when customer Simon Hackett drove the entire 313 miles (504 km) of Australia's annual Global Green Challenge on a single charge.[41] The Roadster can be fully recharged in about 3.5 hours from a 220-volt, 70-amp home outlet.[42]

Several automakers and independent third-party companies are working on standard replaceable battery packs -- energy storage devices that could be "swapped" at conveniently located service stations in about as much time as a gasoline tank refill.[43] The old battery would be recharged and the customer would essentially lease a fully charged one.[44] Better Place demonstrated a car going through a battery switch station, switching the battery in just 1 minute, 13 seconds. The process is cleaner and faster than filling a tank with gasoline and the driver remains in the car the entire time.[45]. With a plan to fill different cities, states and countries (Israel and California are just two of them) around the globe with battery switch stations[46], the electric cars with a contract with Better Place will have virtually unlimited range because of battery swapping and be sold at a price lower than $20000 before incentives.[47]. The Tesla Model S sedan (a five-person car expected to be launched in 2012) is expected to have a swappable battery.[48] The battery swap time will be just 1 minute.[49] Tesla Model S customers will be able to swap batteries at Tesla dealerships with the possibility to rent 300 mile batteries for longer trips.[50]

In addition, it is expected to have quick-charge stations with high-speed charging capability from 440-volt Three-phase industrial outlets so that consumers could refill in roughly 20-30 minutes.[51] The downside is that as of August 2010 there are no high-speed quick-charge stations in North America apart from the first one in Portland, Oregon.

In April 21, 2010, Sanyo announced that it performed a 555.6 km (345.2 mile) travel from Tokyo to Osaka on a single charge with an electric Li-Ion batteries powered Daihatsu Mira.[52] May 25, 2010, Sanyo announced breaking its own record with a 1003 km (623 mile) travel. It took 27.5 hours at an average speed of 25 mph (40 kph) at a training school for auto racers in Ibaraki[53]

Carbon dioxide emissions

Electric cars produce no pollution at the tailpipe, but their use increases demand for electricity generation. Generating electricity and producing liquid fuels for vehicles are different categories of the energy economy, with different inefficiencies and environmental harms, but both emit carbon dioxide into the environment that must be accounted for in a "well to wheel" (WTW) comparison. An electric car's WTW emissions are much lower in a country like Canada, which electricity supply is dominated by hydro and nuclear, than in countries like China and the US that rely heavily on coal.

An EV recharged from the existing US grid electricity emits about 115 grams of CO2 per kilometer driven (6.5 oz(CO2)/mi), whereas a conventional US-market gasoline powered car emits 250 g(CO2)/km (14 oz(CO2)/mi) (most from its tailpipe, some from the production and distribution of gasoline).[54] The savings are questionable relative to hybrid or diesel cars, (according to official British government testing, the most efficient European market cars are well below 115 grams of CO2 per kilometer driven, although a study in Scotland gave 81.4g CO2/km[55]), but would be more significant in countries with cleaner electric infrastructure. In a worst case scenario where incremental electricity demand would be met exclusively with coal, a 2009 study conducted by the WWF, World Wide Fund for Nature, and IZES found that a mid-size EV would emit roughly 200 g(CO2)/km (11 oz(CO2)/mi), compared with an average of 170 g(CO2)/km (9.7 oz(CO2)/mi) for a gasoline powered compact car.[56] This study concluded that introducing 1 million EV cars to Germany would, in the best case scenario, only reduce CO2 emissions by 0.1%, if nothing is done to upgrade the electricity infrastructure or manage demand.[56]

Like any other vehicles, EVs themselves of course differ in their fuel efficiency and their total cost of ownership, including the environmental costs of their manufacture and disposal.

According to the US Department of Energy, most electricity generation in the United States is from fossil sources, and almost half of that is from coal.[57] Coal is more carbon-intensive than oil. Overall average efficiency from US power plants (33% efficient) to point of use (transmission loss 9.5%) is 30%.[57] Accepting a 70% to 80% efficiency for the electric vehicle gives a figure of only around 20% overall efficiency when recharged from fossil fuels. That is comparable to the efficiency of an internal combustion engine running at variable load. The efficiency of a gasoline engine is about 16%, and 20% for a diesel engine.[58][59] This is much lower than the efficiency when running at constant load and optimal rotational speed, which gives efficiency around 30% and 45% respectively.[60] The electric battery suffers a smaller decrease in efficiency when running at variable load,[61] which accounts for the modest increased efficiency of hybrid vehicles. The actual result in terms of emissions depends on different refining and transportation costs getting fuel to a car versus a power plant. Diesel engines can also easily run on renewable fuels, biodiesel, vegetable oil fuel, with no loss of efficiency. Using fossil based grid electricity partially negates the high in-vehicle efficiency advantages of electric cars, though even with that drawback, the operation of a electric vehicle has a smaller carbon footprint than a gasoline car. This is because internal combustion engines, when used for propelling a vehicle, operate throughout their power band, which is hardly optimal for efficiency. A major potential benefit of electric cars is to allow diverse renewable electricity sources to fuel cars. A electric vehicle, recharged from renewable resources, would produce no CO2 emissions at all.

According to the US Department of Energy, CO2 emissions for electricity generated from coal result in 2.05 lb (0.93 kg) of CO2 per kW·h or roughly 0.5 lb(CO2)/mi (). CO2 emissions from electricity produced from all types of fuel using the mix of sources in the US as of 2008 results in 1.35 lb (0.61 kg) of CO2 per kW·h or 0.337 pounds of CO2 per mile () from an electric vehicle with a 0.250- (0.155 ; 0.56 MJ/km) energy consumption (typical). Gasoline used in Internal Combustion Engine automobiles produces 19.5 lbCO2/US gal () directly and an undetermined amount of CO2 in refining the crude oil, and transporting the gasoline to retail point of sale. With a US fleet average of 21.3 mpg-US (11.0 L/100 km; 25.6 mpg-imp) in 2008, this would indicate a CO2 production of 0.915 lb/mi () driven. Electric powered automobiles, even using the most CO2 intensive coal produced electricity, produce half the emissions of gasoline powered automobiles.[62]

If solar, wind, hydro, or nuclear electric generation, or carbon capture for fossil fuel powered plants were to become prevalent, electric vehicles could produce less CO2, potentially zero. Based on GREET simulations, electric cars can achieve up to 100% reductions with renewable electric generation, against 77% with a B100 car. At present only a 32% reduction of CO2 is available for electric cars recharging from non-renewable utilities on the US Grid, because of the majority use of fossil fuels in generation, and inefficiency in the grid itself.[57][63][64]

Acceleration and drivetrain design

Electric motors can provide high power to weight ratios, and batteries can be designed to supply the large currents to support these motors.

Although some electric vehicles have very small motors, 15 kW (20 hp) or less and therefore have modest acceleration, many electric cars have large motors and brisk acceleration. In addition, the relatively constant torque of an electric motor, even at very low speeds tends to increase the acceleration performance of an electric vehicle relative to that of the same rated motor power internal combustion engine. Another early solution was American Motors’ experimental Amitron piggyback system of batteries with one type designed for sustained speeds while a different set boosted acceleration when needed.

Electric vehicles can also use a direct motor-to-wheel configuration which increases the amount of available power. Having multiple motors connected directly to the wheels allows for each of the wheels to be used for both propulsion and as braking systems, thereby increasing traction. In some cases, the motor can be housed directly in the wheel, such as in the Whispering Wheel design, which lowers the vehicle's center of gravity and reduces the number of moving parts. When not fitted with an axle, differential, or transmission, electric vehicles have less drivetrain rotational inertia.

When the foot is lifted from the accelerator of an ICE, engine braking causes the car to slow. An EV would coast under these conditions, and applying mild regenerative braking instead provides a more familiar response.

A gearless or single gear design in some EVs eliminates the need for gear shifting, giving such vehicles both smoother acceleration and smoother braking. Because the torque of an electric motor is a function of current, not rotational speed, electric vehicles have a high torque over a larger range of speeds during acceleration, as compared to an internal combustion engine. As there is no delay in developing torque in an EV, EV drivers report generally high satisfaction with acceleration.

For example, the Venturi Fetish delivers supercar acceleration despite a relatively modest 220 kW (295 hp), and top speed of around 160 km/h (100 mph). Some DC motor-equipped drag racer EVs, have simple two-speed transmissions to improve top speed.[65] The Tesla Roadster prototype can reach 100 km/h (62 mph) in 4 seconds with a motor rated at 185 kW (248 hp).[66]

Energy efficiency

Internal combustion engines are relatively inefficient at converting on-board fuel energy to propulsion as most of the energy is wasted as heat. On the other hand, electric motors are more efficient in converting stored energy into driving a vehicle, and electric drive vehicles do not consume energy while at rest or coasting, and some of the energy lost when braking is captured and reused through regenerative braking, which captures as much as one fifth of the energy normally lost during braking.[69][70] Typically, conventional gasoline engines effectively use only 15% of the fuel energy content to move the vehicle or to power accessories, and diesel engines can reach on-board efficiencies of 20%, while electric drive vehicles have on-board efficiency of around 80%.[69]

Production and conversion electric cars typically use 10 to 23 kW·h/100 km (0.17 to 0.37 kW·h/mi).[36][71] Approximately 20% of this power consumption is due to inefficiencies in charging the batteries. Tesla Motors indicates that the vehicle efficiency (including charging inefficiencies) of their lithium-ion battery powered vehicle is 12.7 kW·h/100 km (0.21 kW·h/mi) and the well-to-wheels efficiency (assuming the electricity is generated from natural gas) is 24.4 kW·h/100 km (0.39 kW·h/mi).[72] The US fleet average of 10 l/100 km (24 mpg-US) of gasoline is equivalent to 96 kW·h/100 km (1.58 kW·h/mi), and the Honda Insight uses 32 kW·h/100 km (0.52 kW·h/mi) (assuming 9.6 kW·h per liter of gasoline).

The waste heat generated by an ICE is frequently put to beneficial use by heating the vehicle interior. Electric vehicles generate very little waste heat and resistance electric heat may have to be used to heat the interior of the vehicle if heat generated from battery charging/discharging can not be used to heat the interior. Electric vehicles used in cold weather will show increased energy consumption and reduced battery capacity and so decreased range on a single charge, for example the Mini E's range dropped by 30% in cold weather.[73]

Safety

The safety issues of BEVs are largely dealt with by the international standard ISO 6469. This document is divided in three parts dealing with specific issues:

- On-board electrical energy storage, i.e. the battery

- Functional safety means and protection against failures

- Protection of persons against electrical hazards.

Firefighters and rescue personnel receive special training to deal with the higher voltages and chemicals encountered in electric and hybrid electric vehicle accidents. While BEV accidents may present unusual problems, such as fires and fumes resulting from rapid battery discharge, there is apparently no available information regarding whether they are inherently more or less dangerous than gasoline or diesel internal combustion vehicles which carry flammable fuels.

Vehicle safety

Great effort is taken to keep the mass of an electric vehicle as low as possible, in order to improve the EV's range and endurance. Despite these efforts, the high density and weight of the electric batteries usually results in an EV being heavier than a similar equivalent gasoline vehicle leading to less interior space, and longer braking distances. However, in a collision, the occupants of a heavy vehicle will, on average, suffer fewer and less serious injuries than the occupants of a lighter vehicle; therefore, the additional weight brings safety benefits[76] despite having a negative effect on the car's performance.[77] An accident in a 2,000 lb (900 kg) vehicle will on average cause about 50% more injuries to its occupants than a 3,000 lb (1,400 kg) vehicle.[78][79] In a single car accident, and for the other car in a two car accident, the increased mass causes an increase in accelerations and hence an increase in the severity of the accident. Some electric cars use low rolling resistance tires, which typically offer less grip than normal tires.[80][81][82] Many electric cars have a small, light and fragile body, though, and therefore offer inadequate safety protection. Because of this, the Insurance Institute for Highway Safety in America had condemned the use of such vehicles.[83]

Hazard to pedestrians

At low speeds, electric cars produced less roadway noise as compared to vehicles propelled by a internal combustion engine. Blind people or the visually impaired consider the noise of combustion engines a helpful aid while crossing streets, hence electric cars and hybrids could pose an unexpected hazard.[84][85] Tests have shown that this is a valid concern, as vehicles operating in electric mode can be particularly hard to hear below 20 mph (30 km/h) for all types of road users and not only the visually impaired. At higher speeds the sound created by tire friction and the air displaced by the vehicle start to make sufficient audible noise.[85]

The US Congress, the European Commission and the Government of Japan are exploring legislation to establish a minimum level of sound for hybrids and plug-in electric vehicles when operating in electric mode, so that blind people and other pedestrians and cyclists can hear them coming and detect from which direction they are approaching.[85][86] The Nissan Leaf will be the first electric car to include Nissan's Vehicle Sound for Pedestrians system, which will include one sound for forward motion and another for reverse.[87][88]

Cabin heating and cooling

While heating can be simply provided with an electric resistance heater, higher efficiency and integral cooling can be obtained with a reversible heat pump (this is currently implemented in the hybrid Toyota Prius). Positive Temperature Coefficient (PTC) junction cooling[89] is also attractive for its simplicity - this kind of system is used for example in the Tesla Roadster. However some electric cars, for example the Citroën Berlingo Electrique, use an auxiliary heating system (for example gasoline-fueled units manufactured by Webasto or Eberspächer). Cabin cooling can be augmented with solar power, most simply and effectively by inducting outside air to avoid extreme heat buildup when the vehicle is closed and parked in the sunlight (such cooling mechanisms are available as aftermarket kits for conventional vehicles). Two models of the 2010 Toyota Prius include this feature as an option.[90]

Regenerative braking

Using regenerative braking, a feature which is present on many hybrid electric vehicles, approximately 20% of the energy usually lost in the brakes is recovered to recharge the batteries.[70]

Batteries

Rechargeable battery materials used in electric vehicles include lead-acid ("flooded" and VRLA), NiCd, nickel metal hydride, lithium-ion, Li-ion polymer, and, less commonly, zinc-air and molten salt. The Lithium iron phosphate battery is currently one of the most promising electric vehicle battery variants due to its light weight, high specific energy, and lack of thermal runaway issues that have plagued laptop computer lithium-ion batteries. The amount of electricity stored in batteries is measured in ampere hours or coulombs, with the total energy often measured in watt hours.

Historically, EVs and PHEVs have had problems with high battery costs, limited range between battery recharging, charging time, and battery lifespan, which have limited their widespread adoption. Ongoing battery technology advancements have reduced many of these problems; many models have recently been prototyped, and a few future production models have been announced.

Charging

Batteries in BEVs must be periodically recharged (see also Replacing, below). BEVs most commonly charge from the power grid (at home or using a street or shop charging station), which is in turn generated from a variety of domestic resources; such as coal, hydroelectricity, nuclear and others. Home power such as roof top photovoltaic solar cell panels, micro hydro or wind may also be used and are promoted because of concerns regarding global warming.

Level 1, 2, and 3 charging

Around 1998 the California Air Resources Board classified levels of charging power that have been codified in title 13 of the California Code of Regulations, the U.S. 1999 National Electrical Code section 625 and SAE International standards.

| Level | Original definition[91] | Coulomb Technologies' definition[92] | Connectors |

|---|---|---|---|

| Level 1 | AC energy to the vehicle's on-board charger; from the most common U.S. grounded household receptacle, commonly referred to as a 120 volt outlet. | 120 V AC; 16 A | SAE J1772 (16.8 kW) |

| Level 2 | AC energy to the vehicle's on-board charger;208-240 volt, single phase. The maximum current specified is 32 amps (continuous) with a branch circuit breaker rated at 40 amps. Maximum continuous input power is specified as 7.68 kW. | 208-240 V AC; 12 A to 80 A |

SAE J1772 (16.8 kW) IEC 62196 (44 kW) Magne Charge IEC 60309 16 A (3.8 kW) |

| Level 3 | DC energy from an off-board charger; there is no minimum energy requirement but the maximum current specified is 400 amps and 240 kW continuous power supplied. | very high voltages (300-500 V DC); very high currents (100s of Amperes) | CHΛdeMO (62.5 kW) |

The term "Level 3" has also been used by the SAE J1772 Connector Standard Committee for a possible future higher-power AC fast charging connector.[93] SAE has not approved standards for either higher-power connector.[94]

Connectors

Most electric cars have used conductive coupling to supply electricity for recharging after the California Air Resources Board settled on the SAE J1772-2001 standard[95] as the charging interface for electric vehicles in California in June 2001.[96]

- Level 1 charging can be as simple as a mains lead from the car into a weatherproof socket

- Level 2 charging at low current may be possible with a mains lead at the higher voltage that is standard across Europe and the majority of the world and that is available from North American dryer sockets. However, depending on local electrical regulations, a dedicated charging station may be required with a special high-capacity cable running to the car with connectors and signaling logic to protect the user from the higher voltage. For example, in the U.S. electrical regulations require the charging station to be permanently wired to an AC outlet and the cable to have an interlock that de-energizes the electric vehicle connector and its cable whenever the electric connector is uncoupled from the electric vehicle.[97]

- Level 3 charging always requires an external rectifier to convert voltage to high voltage DC with a special electrical connection, special cabling, and signalling logic.

Modern standards for connectors include SAE J1772-2009 (level 1 and 2 charging), IEC 62196 VDE-AR-E 2623-2-2 (level 1, 2 and three-phase charging), and CHAdeMO (level 3 charging).

Another approach is inductive charging using a non-conducting "paddle" inserted into a slot in the car. Delco Electronics developed the Magne Charge inductive charging system around 1998 for the General Motors EV1 and it was also used for the Chevrolet S-10 EV and Toyota RAV4 EV vehicles.

Charging time

More electrical power to the car reduces charging time. Power is limited by the capacity of the grid connection, and, for level 1 and 2 charging, by the power rating of the car's on-board charger. A normal household outlet is between 1.5 kW (in the US, Canada, Japan, and other countries with 110 volt supply) to 3 kW (in countries with 230V supply). The main connection to a house might be able to sustain 10 kW, and special wiring can be installed to use this. As examples of on-board chargers, the Nissan Leaf at launch will have a 3.3 kW charger[98] and the Tesla Roadster appears to accept 16.8 kW (240V at 70A) from the Tesla Home Connector.[99] These power numbers are small compared to the effective power delivery rate of an average petrol pump, about 5,000 kW. Even if the electrical supply power can be increased, most batteries do not accept charge at greater than their charge rate ("1C"), because high charge rates have an adverse effect on the discharge capacities of batteries.[100] Despite these power limitations, plugging in to even the least-powerful conventional home outlet provides more than 15 kilowatt-hours of energy overnight, sufficient to propel most electric cars more than 70 kilometres (43 mi) (see Energy efficiency below).

Faster charging

In 1995, some charging stations charged BEVs in one hour. In November 1997, Ford purchased a fast-charge system produced by AeroVironment called "PosiCharge" for testing its fleets of Ranger EVs, which charged their lead-acid batteries in between six and fifteen minutes. In February 1998, General Motors announced a version of its "Magne Charge" system which could recharge NiMH batteries in about ten minutes, providing a range of 60 to 100 mi (100 to 160 km).[101]

In 2005, mobile device battery designs by Toshiba were claimed to be able to accept an 80% charge in as little as 60 seconds.[102] Scaling this specific power characteristic up to the same 7 kW·h EV pack would result in the need for a peak of 340 kW from some source for those 60 seconds. It is not clear that such batteries will work directly in BEVs as heat build-up may make them unsafe.

Altairnano's NanoSafe batteries can be recharged in several minutes, versus hours required for other rechargeable batteries. A NanoSafe cell can be charged to around 95% charge capacity in approximately 10 minutes.[103][104]

Japanese company, JFE Engineering, has developed a quick charger that it claims needs three minutes for a 50% charge, or five minutes for a 70% charge.[105]

Most people do not usually require fast recharging because they have enough time, 30 minutes to six hours (depending on discharge level) during the work day or overnight at home to recharge. The charging does not require attention so it takes only a few seconds of the owner's time for plugging and unplugging the charging source. BEV drivers frequently prefer recharging at home, avoiding the inconvenience of visiting a public charging station. Some workplaces provide special parking bays for electric vehicles with chargers provided - sometimes powered by solar panels. In colder areas such as Finland, some northern US states and Canada there already exists some infrastructure for public power outlets, in parking garages and at parking meters, provided primarily for use by block heaters and set with circuit breakers that prevent large current draws for other uses.[106]

Travel range before recharging

The range of an electric car depends on the number and type of batteries used. The weight and type of vehicle, and the performance demands of the driver, also have an impact just as they do on the range of traditional vehicles. The range of an electric vehicle conversion depends on the battery type:

- Lead acid batteries are still the most used form of power for most of the electric vehicles used today. Compared to e.g. lithium-ion batteries, they are up to 3x cheaper. The initial construction costs are significantly lower than for other battery types, and while power output to weight is poorer than other designs, range and power can be easily added by increasing the number of batteries.[107]

- Manufacturers are not using these batteries in new designs because of the greater maintenance costs compared with solid batteries and the weight and bulk which affects the handling and space of the vehicle.

- They are the principal form of battery in non-road going electric vehicles such as mobility scooters and electric forklifts.

- Most non-commercial conversions generally have a range of 30 to 80 km (20 to 50 mi). Production EVs with lead-acid batteries are capable of up to 130 km (80 mi) per charge.

- NiMH batteries have higher specific energy and may deliver up to 200 km (120 mi) of range.

- The lithium-ion battery in the AC Propulsion tzero provides 400 to 500 km (200 to 300 mi) of range per charge.[108] The list price of this vehicle when it was released in 2003 was US$220,000.[109]

Finding the economic balance of range against performance, battery capacity versus weight, and battery type versus cost challenges every EV manufacturer.

Replacing

An alternative to quick recharging is to exchange the drained or nearly drained batteries (or battery range extender modules) with fully charged batteries, rather as stagecoach horses were changed at coaching inns. Batteries could be leased or rented instead of bought, and then maintenance deferred to the leasing or rental company, and ensures availability. In 1947, in Nissan's first electric car, the batteries were removable so that they could be replaced at filling stations with fully charged ones. Renault announced at the 2009 Frankfurt Motor Show that they have sponsored a network of charging stations and plug-in plug-out battery swap stations.[110] Other vehicle manufacturers and companies are also investigating the possibility.

Replaceable batteries were used in the electric buses at the 2008 Summer Olympics.[111]

Refilling

Zinc-bromine flow batteries or Vanadium redox batteries can be refilled, instead of recharged, saving time. The depleted electrolyte can be recharged at the point of exchange, or taken away to a remote station.

Vehicle-to-grid: uploading and grid buffering

A Smart grid allows BEVs to provide power to the grid, specifically:

- During peak load periods, when the cost of electricity can be very high. These vehicles can then be recharged during off-peak hours at cheaper rates while helping to absorb excess night time generation. Here the batteries in the vehicles serve as a distributed storage system to buffer power.

- During blackouts, as an emergency backup supply.

The basic premise here is similar to Economy 7 in the United Kingdom: incentives to spread the load more evenly across the day reduces the need for expensive peak demand and thus the need to building power stations that can supply it on demand.

Lifespan

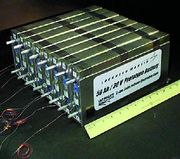

Individual batteries are usually arranged into large battery packs of various voltage and ampere-hour capacity products to give the required energy capacity. Battery life should be considered when calculating the extended cost of ownership, as all batteries eventually wear out and must be replaced. The rate at which they expire depends on a number of factors.

The depth of discharge (DOD) is the recommended proportion of the total available energy storage for which that battery will achieve its rated cycles. Deep cycle lead-acid batteries generally should not be discharged below 80% capacity. More modern formulations can survive deeper cycles.

In real world use, some fleet Toyota RAV4 EVs, using NiMH batteries will exceed 160 000 km (100,000 mi), and have had little degradation in their daily range.[112] Quoting that report's concluding assessment:

The five-vehicle test is demonstrating the long-term durability of Nickel Metal Hydride batteries and electric drive trains. Only slight performance degradation has been observed to-date on four out of five vehicles.... EVTC test data provide strong evidence that all five vehicles will exceed the 100,000-mile (160,000 km) mark. SCE’s positive experience points to the very strong likelihood of a 130,000-to-150,000-mile (210,000 to 240,000 km) Nickel Metal Hydride battery and drive-train operational life. EVs can therefore match or exceed the lifecycle miles of comparable internal combustion engine vehicles.In June 2003 the 320 RAV4 EVs of the SCE fleet were used primarily by meter readers, service managers, field representatives, service planners and mail handlers, and for security patrols and carpools. In five years of operation, the RAV4 EV fleet had logged more than 6.9 million miles, eliminating about 830 tons of air pollutants, and preventing more than 3,700 tons of tailpipe CO2 emissions. Given the successful operation of its EVs to-date, SCE plans to continue using them well after they all log 100,000 miles (160,000 km).

Jay Leno's 1909 Baker Electric still operates on its original Edison cells. Battery replacement costs of BEVs may be partially or fully offset by the elimination of some regular maintenance, such as oil and filter changes required for ICEVs, and by the greater reliability of BEVs due to their fewer moving parts. They also do away with many other parts that normally require servicing and maintenance in a regular car, such as on the gearbox, cooling system, and engine tuning. And by the time batteries do finally need definitive replacement, they can be replaced with later generation ones which may offer better performance characteristics, in the same way one might replace an old laptop or mobile phone battery.

Future

Battery technology

The future of battery electric vehicles depends primarily upon the cost and availability of batteries with high specific energy, power density, short charge time and long life, as all other aspects such as motors, motor controllers, and chargers are fairly mature and cost-competitive with internal combustion engine components. Li-ion, Li-poly and zinc-air batteries have demonstrated specific energy high enough to deliver range and recharge times comparable to conventional vehicles.By the year 2020, an estimated 30% of the cars driving on the road will be battery, electric or plug-in hybrid.[115]

It is estimated that there are sufficient lithium reserves to power 4 billion electric cars.[116]

The cathodes of early 2007 lithium-ion batteries are made from lithium-cobalt metal oxide. That material is expensive, and can release oxygen if its cell is overcharged. If the cobalt is replaced with iron phosphates, the cells will not burn or release oxygen under any charge. The price premium for early 2007 hybrids is about US$5,000, some US$3,000 of which is for their NiMH battery packs. At early 2007 gasoline and electricity prices, that would break even after six to ten years of operation. The hybrid premium could fall to US$2,000 in five years, with US$1,200 or more of that being cost of lithium-ion batteries, breaking even after three years.[117]

Other methods of energy storage

Experimental supercapacitors and flywheel energy storage devices offer comparable storage capacity, faster charging, and lower volatility. They have the potential to overtake batteries as the preferred rechargeable storage for EVs.[118][119] The FIA included their use in its sporting regulations of energy systems for Formula One race vehicles in 2007 (for supercapacitors) and 2009 (for flywheel energy storage devices).

EEStor claims to have developed a supercapacitor for electricity storage. These units are titanate coated with aluminum oxide and glass to achieve a level of capacitance claimed to be much higher than that currently available on the market. The claimed specific energy is 1.0 MJ/kg whereas existing commercial supercapacitors typically have an specific energy of around 0.01 MJ/kg, while lithium-ion batteries have a specific energy of around 0.59 MJ/kg to 0.95 MJ/kg). EEStor claims that a 5 minute charge should give the supercapacitor enough energy to give a car a range of 400 km (250 mi).[120]

Solar cars

Solar cars are electric cars that derive most or all of their electricity from built in solar panels. After the 2005 World Solar Challenge established that solar race cars could exceed highway speeds, the specifications were changed to provide for vehicles that with little modification could be used for transportation.

Electric car use by country

Hobbyists, conversions, and racing

Hobbyists often build their own EVs by converting existing production cars to run solely on electricity. There is a cottage industry supporting the conversion and construction of BEVs by hobbyists. Universities such as the University of California, Irvine even build their own custom electric or hybrid-electric cars from scratch.

Short-range battery electric vehicles can offer the hobbyist comfort, utility, and quickness, sacrificing only range. Short-range EVs may be built using high-performance lead–acid batteries, using about half the mass needed for a 100 to 130 km (60 to 80 mi) range. The result is a vehicle with about a 50 km (30 mi) range, which, when designed with appropriate weight distribution (40/60 front to rear), does not require power steering, offers exceptional acceleration in the lower end of its operating range, and is freeway capable and legal. But their EVs are expensive due to the higher cost for these higher-performance batteries. By including a manual transmission, short-range EVs can obtain both better performance and greater efficiency than the single-speed EVs developed by major manufacturers. Unlike the converted golf carts used for neighborhood electric vehicles, short-range EVs may be operated on typical suburban throughways (where 60 to 70 km/h (37 to 43 mph) speed limits are typical) and can keep up with traffic typical on such roads and the short "slow-lane" on-and-off segments of freeways common in suburban areas.

Faced with chronic fuel shortage on the Gaza Strip, Palestinian electrical engineer Waseem Othman al-Khozendar invented in 2008 a way to convert his car to run on 32 electric batteries. According to al-Khozendar, the batteries can be charged with US$2 worth of electricity to drive from 180 to 240 km (110 to 150 mi). After a 7-hour charge, the car should also be able to run up to a speed of 100 km/h (60 mph). As electricity is supplied to Gaza by Israel, this may be seen not only as a way to combat climate changes and fuel shortage, but also as a way of making peace.[121][122]

Japanese Professor Hiroshi Shimizu from Faculty of Environmental Information of the Keio University created an electric limousine: the Eliica (Electric Lithium-Ion Car) has eight wheels with electric 55 kW hub motors (8WD) with an output of 470 kW and zero emissions, a top speed of 370 km/h (230 mph), and a maximum range of 320 km (200 mi) provided by lithium-ion batteries.[123] However, current models cost approximately US$300,000, about one third of which is the cost of the batteries.

In 2008, several Chinese manufacturers began marketing lithium iron phosphate (LiFePO4) batteries directly to hobbyists and vehicle conversion shops. These batteries offered much better power to weight ratios allowing vehicle conversions to typically achieve 75 to 150 mi (120 to 240 km) per charge. Prices gradually declined to approximately US$350 per kW·h by mid 2009. As the LiFePO4 cells feature life ratings of 3,000 cycles, compared to typical lead acid battery ratings of 300 cycles, the life expectancy of LiFePO4 cells is around 10 years. This has led to a resurgence in the number of vehicles converted by individuals. LiFePO4 cells do require more expensive battery management and charging systems than lead acid batteries.

Currently available electric cars

There are several types of electric cars available in regional markets such as neighborhood electric vehicles, electric city cars and highway-capable electric cars such as the Tesla Roadster in the U.S. and Europe, and the Mitsubishi i MiEV in Japan and Hong Kong. There are also many electric car projects that are not yet available but are at an advanced stage of development or field testing, such as the Nissan Leaf and the Mini E.

Several countries have established grants and tax credits for the purchase of new electric cars depending on battery size. The U.S. offers a federal income tax credit up to US$7,500,.[124] and several states have additional incentives.[125] The U.K. offers a purchase grant up to a maximum of GB£5,000 (US$7,600) beginning in January 2011.[126][127] As of April 2010, 15 European Union member states provide tax incentives for electrically chargeable vehicles, which consist of tax reductions and exemptions, as well as of bonus payments for buyers of PEVs and hybrid vehicles.[128][129]

Prototype electric cars

The following electric cars are currently in an advanced stage of development.

Highway capable

Cars capable of at least 100 km/h (62 mph)

| Model | Top speed | Acceleration | Capacity Adults+kids |

Charging time | Nominal range | Market release date |

|---|---|---|---|---|---|---|

| Wheego Whip LiFe | 105 km/h (65 mph) |

|

161 km (100 mi) | Sept 2010 | ||

| Nissan Leaf | 145 km/h (90 mph) |

|

8 hours with standard AC power; 30 minute rapid charge to 80% | 161 km (100 mi) | Dec 2010 | |

| CODA Sedan | 129 km/h (80 mph) | 0–60 mi/h in 11 seconds |

|

full charge in approx. 6 hours | 193 km (120 mi) | Late 2010 |

| REVA NXR | 104 km/h (65 mph) |

|

160 km (99 mi) | Late 2010 | ||

| Tesla Model S | 193 km/h (120 mph) | 0 to 97 km/h (0 to 60 mph) in 5.6 s |

|

Full charge 3.5 hours using the High Power Connector or 45 minute QuickCharge | 483 km (300 mi) | 2011 |

| DOK-ING XD Concept | 130 km/h (81 mph) | 0–100 km/h in 7.7 seconds |

|

0-80% approx. 6 hours, 230 V/16A

0-100% approx. 8 hours, 230 V/16A |

250 km (160 mi) | 2011 |

See also

- Alternative fuel vehicle

- Compressed air car

- Electric car use by country

- Electric boat

- Electric bus

- Electric motorcycles and scooters

- Electric vehicle conversion

- Environmental Transport Association

- Hybrid electric vehicle (HEV)

- List of emerging technologies

- List of production battery electric vehicles

- Neighborhood electric vehicle

- Plug-in electric vehicle (PEV)

- Plug-in hybrid (PHEV)

- Project Better Place - creation of a market-based transportation infrastructure that supports electric vehicles

- Rechargeable battery

- Vehicle-to-grid

References

- ↑ "Nissan Prices LEAF in Japan Starting at ¥3.76M (US$40.5K); Mitsubishi Begins Sales of i-MiEV to Individuals at ¥3.98M". Green Car Congress. 2010-03-30. http://www.greencarcongress.com/2010/03/leaf-imiev-20100330.html#more. Retrieved 2010-04-24.

- ↑ "Mitsubishi Begins Sales of i-MiEV to Individuals in Hong Kong; First Individual Sales Outside of Japan". Green Car Congress. 2010-05-20. http://www.greencarcongress.com/2010/05/hksar-20100520.html#more. Retrieved 2010-05-21.

- ↑ "Better Places debuts EV fleet of taxis and opening of battery swap stations". betterplaces.com. http://www.betterplace.com/global-progress-japan. Retrieved 2010-06-28.

- ↑ "Should Pollution Factor Into Electric Car Rollout Plans?". Earth2tech.com. 2010-03-17. http://earth2tech.com/2010/03/17/should-pollution-factor-into-electric-car-rollout-plans/. Retrieved 2010-04-18.

- ↑ "Electro Automotive: FAQ on Electric Car Efficiency & Pollution". Electroauto.com. http://www.electroauto.com/info/pollmyth.shtml. Retrieved 2010-04-18.

- ↑ http://www.cleanairnet.org/baq2003/1496/articles-58076_resource_1.doc

- ↑ "Plug-in Hybrid Cars: Chart of CO2 Emissions Ranked by Power Source". TreeHugger. http://www.treehugger.com/files/2008/04/plug-in-hybrid-cars-co2-emissions-electricity-energy.php. Retrieved 2010-04-18.

- ↑ "D:\MYDOCS\WPDOCS\1605B\EFACTO~1.WPD" (PDF). http://www.eia.doe.gov/pub/oiaf/1605/cdrom/pdf/e-supdoc.pdf. Retrieved 2010-07-16.

- ↑ 9.0 9.1 "Electric Power Monthly - Table 1.1. Net Generation by Energy Source". Eia.doe.gov. http://www.eia.doe.gov/cneaf/electricity/epm/table1_1.html. Retrieved 2010-04-18.

- ↑ United_States_emission_standards#Electricity_generation

- ↑ "Less CO2". My Electric Car. http://www.myelectriccar.com.au/co2.html. Retrieved 2010-04-18.

- ↑ http://www.mckinsey.com/locations/greaterchina/mckonchina/pdfs/China_Charges_Up.pdf

- ↑ ...the four electric vehicles analysed in this study consume around 1.7 times less primary energy and generate less than half the CO2 of a Toyota Prius... http://www.going-electric.org/docs/studies/CO2-energy-electric-vehicles.pdf

- ↑ Palm, Erik (2009-05-01). "Study: Electric cars not as green as you think | Green Tech - CNET News". News.cnet.com. http://news.cnet.com/8301-11128_3-10231102-54.html. Retrieved 2010-04-18.

- ↑ "Ford says auto future hinges on electric car | freep.com | Detroit Free Press". freep.com. http://www.freep.com/article/20100416/BUSINESS01/4160304/1002/business/Ford-Electric-car-is-autos-future. Retrieved 2010-04-18.

- ↑ By Martin LaMonica (2009-02-02). "Plotting the long road to one million electric cars". CNN.com. http://www.cnn.com/2009/TECH/02/02/electric.vehicles/index.html. Retrieved 2010-04-18.

- ↑ Terry Macalister (2010-04-11). "US military warns oil output may dip causing massive shortages by 2015 | Business". London: The Guardian. http://www.guardian.co.uk/business/2010/apr/11/peak-oil-production-supply. Retrieved 2010-04-18.

- ↑ Terry Macalister (2010-02-07). "Branson warns of oil crunch within five years | Business". London: The Guardian. http://www.guardian.co.uk/business/2010/feb/07/branson-warns-peak-oil-close. Retrieved 2010-04-18.

- ↑ Loveday, Eric (2010-06-08). "ALG predicts gas at $4.13 by 2013; residual values for compacts, hybrids to climb — Autoblog Green". Green.autoblog.com. http://green.autoblog.com/2010/06/08/alg-predicts-gas-at-4-13-by-2013-residual-values-for-compacts/. Retrieved 2010-07-16.

- ↑ "electric automobile." Encyclopaedia Britannica Online. N.p., n.d. Web. 5 Oct. 2009..

- ↑ Bryce, Robert (25 April 2010). "5 Myths about green energy". Washington, DC: Washington Post. pp. B4. http://www.washingtonpost.com/wp-dyn/content/article/2010/04/23/AR2010042302220.html.

- ↑ Kirsch, David A. (2000). The Electric Vehicle and the Burden of History. New Brunswick, New Jersey, and London: Rutgers University Press. pp. 153–162. ISBN 0-8135-2809-7.

- ↑ by Keith NaughtonDecember 22, 2007 (2007-12-22). "Bob Lutz: The Man Who Revived the Electric Car". Newsweek. http://www.newsweek.com/id/81580. Retrieved 2010-07-16.

- ↑ Friend, Tad (2009-01-07). "Elon Musk and electric cars". The New Yorker. http://www.newyorker.com/reporting/2009/08/24/090824fa_fact_friend. Retrieved 2010-07-16.

- ↑ Yoshio Takahashi (3 August 2009). "Nissan Unveils New Electric Ca". Wall Street Journal. http://online.wsj.com/article/SB124919217149699407.html. Retrieved 2009-08-03.

- ↑ "Nissan LEAF Specs". Nissan. http://www.nissan-zeroemission.com/EN/LEAF/specs.html. Retrieved 2009-08-03.

- ↑ "Worldcarfans site". http://www.worldcarfans.com/9080925.010/all-electric-mini-cooper-spotted-for-first-time.

- ↑ "BMW and UC Davis Partner on MINI E Study". Green Car Congress. 2009-08-14. http://www.greencarcongress.com/2009/08/bmw-ucdavis-20090814.html. Retrieved 2009-12-25.

- ↑ Peter Whoriskey (2009-12-24). "Recharging and other concerns keep electric cars far from mainstream". Washington Post. http://www.washingtonpost.com/wp-dyn/content/article/2009/12/23/AR2009122303463.html?sub=AR. Retrieved 2009-12-25.

- ↑ "BMW Delivers 40 Electric MINI E Cars for UK Trial". Green Car Congress. 2009-12-14. http://www.greencarcongress.com/2009/12/minie-20091214.html. Retrieved 2009-12-25.

- ↑ 31.0 31.1 "Electric Vehicle Charging Rate and Economics". PG&E. http://www.pge.com/about/environment/pge/electricvehicles/fuelrates/index.shtml. Retrieved 2010-06-07.

- ↑ 09:56 PM (2007-06-23). "Tesla Motors Club Forum - FAQ". Teslamotorsclub.com. http://www.teslamotorsclub.com/faq.php#batterycost. Retrieved 2010-07-16.

- ↑ Abuelsamid, Sam (2009-01-17). "Tesla offers laundry list of new options, $12k prepaid battery replacement — Autoblog Green". Green.autoblog.com. http://green.autoblog.com/2009/01/17/tesla-offers-laundry-list-of-new-options-12k-prepaid-battery-r/. Retrieved 2010-07-16.

- ↑ Shai Agassi. (2009-02). Shai Agassi's bold plan for electric cars. Long Beach and Palm Springs, California: TED. Event occurs at 4m10s. http://www.ted.com/talks/shai_agassi_on_electric_cars.html. Retrieved 2009-10-05. "See we're bound by today's technology on batteries, which is about 120 miles if you want to stay within reasonable space and weight limitations. 120 miles is a good enough range for a lot of people. But you never want to get stuck. So what we added as a second element to our network is a battery swap system. You drive. You take your depleted battery out. A full battery comes on. And you drive on. You don't do it as a human being. You do it as a machine. It looks like a car wash. You come into your car wash. And a plate comes up, holds your battery, takes it out, puts it back in. Within two minutes you're back on the road. And you can go again. If you had charge spots everywhere, and you had battery swap stations everywhere, how often would you do it? And it ends up that you'd do swapping less times than you stop at a gas station. As a matter of fact, we add it to the contract. We said that if you stop to swap your battery more than 50 times a year we start paying you money because it's an inconvenience."

- ↑ Andrew Simpson, Tesla Motors Vehicle Systems Engineer (2007-09-24). ""Where the Rubber Meets the Road"". http://www.teslamotors.com/blog4/?p=60. Retrieved 2008-02-22. "Mr. Simpson confirmed via email that "We do not quote station-to-wheel efficiency, but we do quote plug-to-wheel efficiency which includes all energy use downstream of the charging plug. For the most-recent 221 mi (356 km) range test, our plug-to-wheel efficiency was 336 Wh/mi.""

- ↑ 36.0 36.1 (PDF) Performance Statistics - 1999 General Motors EV1 w/NiMH, United States Department of Energy Office of Energy Efficiency and Renewable Energy, 1999, http://www1.eere.energy.gov/vehiclesandfuels/avta/pdfs/fsev/eva_results/ev1_eva.pdf, retrieved 2009-04-25

- ↑ Carpenter, Susan (2010-03-30). "Nissan Leaf's promise: An affordable electric - Los Angeles Times". Articles.latimes.com. http://articles.latimes.com/2010/mar/30/business/la-fi-nissan-leaf31-2010mar31. Retrieved 2010-04-18.

- ↑ 38.0 38.1 Erickson, Glenn (10 January 2009). "DVD Savant Review:Who Killed the Electric Car?". dvdtalk.com. http://www.dvdtalk.com/dvdsavant/s2798who.html. Retrieved 17 November 2009.. See main article Who killed the electric car

- ↑ http://green.autoblog.com/2010/05/04/more-range-anxiety-with-the-mitsubishi-imiev/ green.autoblog.com/2010/05/04/more-range-anxiety-with-the-mitsubishi-imiev

- ↑ "EV WORLDwire: Tesla Receives First Panasonic Lithium-ion Batteries". Evworld.com. http://evworld.com/news.cfm?newsid=23236. Retrieved 2010-07-16.

- ↑ blogs.edmunds.com/greencaradvisor/2009/10/tesla-roadster-logs-new-record-of-313-miles-on-single-charge-in-oz-green-rally.html

- ↑ auto.howstuffworks.com/tesla-roadster.htm

- ↑ [1]

- ↑ wheels.blogs.nytimes.com/2010/04/29/better-place-opens-battery-swap-station-in-tokyo-for-90-day-taxi-trial

- ↑ http://green.autoblog.com/2009/05/13/video-better-place-battery-swapper-demonstrated/

- ↑ http://www.betterplace.com/global-progress-north-america-california

- ↑ http://green.autoblog.com/2009/12/21/better-places-renault-fluence-ev-to-sell-for-under-20-000/

- ↑ http://www.teslamotors.com/media/press_room.php?id=1284 teslamotors.com/media/press_room.php?id=1284

- ↑ http://www.teslamotors.com/models/specs

- ↑ http://www.autoweek.com/article/20090327/CARNEWS/903279971

- ↑ http://green.autoblog.com/2010/08/09/nations-first-public-quick-charge-station-opens-up-in-portland/

- ↑ [2]Akihabara News, Sanyo Li-Ion batteries powered Electric Car to Guiness Record

- ↑ [3]Akihabara News, Sanyo Li-Ion battery powered Electric Vehicle broke its own Guinness Record

- ↑ "Wheel to Well Analysis of EVs" (PDF). MIT Electric Vehicle Team. MIT. April 2008. http://web.mit.edu/evt/summary_wtw.pdf. Retrieved 2009-07-09.

- ↑ Physorg: Electric vehicles given thumbs up

- ↑ 56.0 56.1 Palm, Erik (1 May 2009), Study: Electric cars not as green as you think, CNET Networks, http://news.cnet.com/8301-11128_3-10231102-54.html, retrieved 2009-05-04

- ↑ 57.0 57.1 57.2 Overview of the Electric Grid, United States Department of Energy Office of Electricity Delivery and Energy Reliability, http://www.energetics.com/gridworks/grid.html, retrieved 2009-04-25

- ↑ Johnson, C (15 April 2009), Physics In an Automotive Engine, Public Service Projects at mb-soft.com, http://mb-soft.com/public2/engine.html, retrieved 2009-04-25

- ↑ "Improving IC Engine Efficiency", Energy & Environment (course 341), Washington State University, Autumn 2001, http://courses.washington.edu/me341/oct22v2.htm, retrieved 2009-04-25

- ↑ (PDF) The Environmental Challenge, Volvo, 7 October 2004, p. 9, http://www.volvo.com/internet/vebiz2webauthor/sharepoint/docfetch.aspx?docID=72&listID=a560d670-9b7a-40ff-845b-f34973fc7493&area=VolvoCom+Volvo+Group, retrieved 2005-09-25

- ↑ Valøena, Lars Ole; Shoesmith, Mark I. (10 October 2007) (PDF), The effect of PHEV and HEV duty cycles on battery and battery pack performance, bE-One Moli Energy (Canada) Ltd, http://www.pluginhighway.ca/PHEV2007/proceedings/PluginHwy_PHEV2007_PaperReviewed_Valoen.pdf, retrieved 2009-04-27

- ↑ Carbon Dioxide Emissions from the Generation of Electric Power in the United States, United States Department of Energy, http://www.eia.doe.gov/cneaf/electricity/page/co2_report/co2report.html, retrieved 2009-10-10

- ↑ "Climate Change" (PDF), Why Greener Vehicles Now?, Northeast Sustainable Energy Association (part of the American Solar Energy Society), 18 May 2006, http://www.nesea.org/uploads/universe/docs/wysiwyg/documents/Transportation_Climate_Change.pdf, retrieved 2009-04-25

- ↑ Modeling, Simulation & Assessment, Argonne National Laboratory, http://www.transportation.anl.gov/modeling_simulation/index.html, retrieved 2009-04-05

- ↑ Hedlund, R. (November 2008), The Roger Hedlund 100 MPH Club, National Electric Drag Racing Association, http://nedra.com/100mph_club.html, retrieved 9009-04-25

- ↑ "Performance Specs", Tesla Motors, 15 April 2009, http://www.teslamotors.com/performance/perf_specs.php, retrieved 2009-04-25

- ↑ Tata Indica Vista EV

- ↑ "2 the city - 4 the city :: Home". XD Concept. http://xdconcept.com/. Retrieved 2010-07-16.

- ↑ 69.0 69.1 Saurin D. Shah (2009). Plug-In Electric Vehicles: What Role for Washington? (1st. ed.). The Brookings Institution. ISBN 978-0-8157-0305-1. Chapter 2, pp. 29, 37 and 43.

- ↑ 70.0 70.1 Sperling, Daniel and Deborah Gordon (2009). Two billion cars: driving toward sustainability. Oxford University Press, New York. pp. 23 and 26. ISBN 978-0-19-537664-7.

- ↑ "Advanced Vehicle Testing Activity", Full Size Electric Vehicles, Idaho National Laboratory, 30 May 2006, http://avt.inel.gov/fsev.html, retrieved 2009-04-25

- ↑ Well-to-Wheel, Tesla Motors, http://www.teslamotors.com/efficiency/well_to_wheel.php, retrieved 2009-04-25

- ↑ Loveday, Eric (2009-12-31). "Mini E Range Diminishing in Cold Winter Weather". All Cars Electric. http://www.allcarselectric.com/blog/1041037_mini-e-range-diminishing-in-cold-winter-weather. Retrieved 2010-07-16.

- ↑ World's Most Popular Electric Car Launches in Denmark, Athens, Greece: Ministry of Foreign Affairs, Denmark, 7 January 2009, http://www.ambathen.um.dk/da/menu/Klima/DagligArtikelOmKlimaOgMiljø/WorldsmostpopularelectriccarlaunchesinDenmark.htm, retrieved 2009-08-15

- ↑ About REVA Electric Car Company Private Ltd, REVA, http://www.revaindia.com/aboutus.htm, retrieved 2009-04-27

- ↑ Effectiveness and impact of ... - Google Books. Books.google.com.au. 2002-08. ISBN 9780309076012. http://books.google.com/?id=yRybeDbz8R8C&lpg=PA71&dq=effect%20of%20mass%20on%20a%20vehicle's%20performance&pg=PA71#v=onepage&q=effect%20of%20mass%20on%20a%20vehicle's%20performance. Retrieved 2009-10-17.

- ↑ Ehsani, Mehrdad (2005). Modern electric, hybrid electric ... - Google Books. Books.google.com.au. ISBN 9780849331541. http://books.google.com/?id=a76NLkq-QwIC&lpg=PA22&dq=effect%20of%20mass%20on%20a%20vehicle's%20performance&pg=PA22#v=onepage&q=. Retrieved 2009-10-17.

- ↑ (PDF) Vehicle Weight, Fatality Risk and Crash Compatibility of Model Year 1991-99 Passenger Cars and Light Trucks, National Highway Traffic Safety Administration, October 2003, http://www.nhtsa.dot.gov/cars/rules/regrev/evaluate/pdf/809662.pdf, retrieved 2009-04-25

- ↑ The safest cars of 2003, insure.com, http://www.insure.com/articles/carinsurance/2003-models.html, retrieved 2009-04-25

- ↑ "Low-rolling-resistance tires", Consumer Reports, November 2007, http://www.consumerreports.org/cro/cars/tires-auto-parts/tires/low-rolling-resistance-tires-8-06/overview/0608_low-rolling-resistance-tires_ov.htm, retrieved 2009-04-25 (subscription required for full access)

- ↑ Crowe, Paul (21 July 2008), "Low Rolling Resistance Tires Save Gas", HorsePower Sports, http://horsepowersports.com/low-rolling-resistance-tires-save-gas/, retrieved 2009-04-25

- ↑ Planned EU Requirements for Tires Would Reduce Road Traffic Safety (press release), Hanover: Continental AG, 12 November 2007, http://www.conti-online.com/generator/www/com/en/continental/portal/themes/press_services/press_releases/safety/pr_2007_11_12_eu_vorgaben_en.html, retrieved 2009-04-25

- ↑ IIHS condemns use of mini trucks and low-speed vehicles on public roads - AutoblogGreen

- ↑ Nuckols, Ben (3 March 2007). "Blind people: Hybrid cars pose hazard". USA Today. http://www.usatoday.com/money/economy/2007-10-03-2698183585_x.htm. Retrieved 2009-05-08.

- ↑ 85.0 85.1 85.2 "Electric cars and noise: The sound of silence". Economist. 7 May 2009. http://www.economist.com/science/displaystory.cfm?story_id=13606446. Retrieved 2009-05-08.

- ↑ Mike King (2010-06-02). "Hybrid cars not noisy enough, group says". The Gazette (Montreal). http://www.montrealgazette.com/technology/Hybrid+cars+noisy+enough+group+says/3100497/story.html. Retrieved 2010-07-04.

- ↑ Jim Motavalli (2010-06-01). "Electric Car Warning Sounds: Don’t Expect Ring Tones". New York Times. http://wheels.blogs.nytimes.com/2010/06/01/electric-car-warning-sounds-dont-expect-ringtones/. Retrieved 2010-06-02.

- ↑ Jim Motavalli (2010-06-17). "Blind Advocates ‘Disappointed’ in Nissan E.V. Sounds for Pedestrians". New York Times. http://wheels.blogs.nytimes.com/2010/06/17/blind-advocates-disappointed-in-nissan-e-v-sounds-for-pedestrians/?ref=automobiles. Retrieved 2010-06-19. The article includes a sample of the two sounds.

- ↑ US 5889260, Golan, Gad & Yuly Galperin, "Electrical PTC heating device", published 30 March 1999

- ↑ "2010 Options and Packages". Toyota Prius. Toyota. http://www.toyota.com/prius-hybrid/options.html. Retrieved 2009-07-09.

- ↑ "PUBLIC HEARING TO CONSIDER PROPOSED AMENDMENTS TO THE CALIFORNIA ZERO EMISSION VEHICLE REGULATIONS REGARDING TREATMENT OF MAJORITY OWNED SMALL OR INTERMEDIATE VOLUME MANUFACTURERS AND INFRASTRUCTURE STANDARDIZATION.". California Air Resources Board. 2001-06-26. http://www.arb.ca.gov/board/books/010628/01-5-1.pdf. Retrieved 2010-05-23.

- ↑ "FAQ: Standards - ChargePoint Network". ChargePoint Network. Coulomb Technologies. http://www.mychargepoint.net/faq-standards.php. Retrieved 2010-05-23.

- ↑ David Herron (2010-07-30). "Electric vehicle charging standards". V is for Voltage Forums. http://visforvoltage.org/book/9471. Retrieved 2010-08-19.

- ↑ John Gartner (2010-08-03). "Fast Vehicle Charging Goes by Many Names". PluginCars.com. http://www.plugincars.com/fast-vehicle-charging-goes-many-names-49817.html. Retrieved 2010-08-19.

- ↑ "Rulemaking: 2001-06-26 Updated and Informative Digest ZEV Infrastructure and Standardization". title 13, California Code of Regulations. California Air Resources Board. 2002-05-13. http://www.arb.ca.gov/regact/charger/uid.pdf. Retrieved 2010-05-23. "Standardization of Charging Systems"

- ↑ California Air Resources Board (2001-06-28). "ARB Amends ZEV Rule: Standardizes Chargers & Addresses Automaker Mergers". Press release. http://www.arb.ca.gov/newsrel/nr062801.htm. Retrieved 2010-05-23. "the ARB approved the staff proposal to select the conductive charging system used by Ford, Honda and several other manufacturers"

- ↑ "NEC 1999 National Electrical Code Article 625 - Electric Vehicle Charging System". National Electrical Code. 1999. http://www.madkatz.com/ev/nec1999Article625.html. Retrieved 2010-06-27.

- ↑ Nick Chambers (2010-05-27). "Nissan LEAF Will Include Fast Charge Capability and Emergency Charging Cable at Launch". gas2.0. http://gas2.org/2010/05/27/nissan-leaf-will-include-fast-charge-capability-and-emergency-charging-cable-at-launch/. Retrieved 2010-06-13.

- ↑ "Tesla Motors - Charging Solutions". Tesla Motors. http://www.teslamotors.com/electric/charging.php. Retrieved 2010-06-13.

- ↑ Buchmann, Isidor (November 2006), The high-power lithium-ion, BatteryUniversity.com (sponsored bv Cadex Electronics Inc.), http://batteryuniversity.com/partone-5A.htm, retrieved 2009-04-25

- ↑ Anderson, C.D.; Anderson, J. (30 June 2004), "New Charging Systems", Electric and Hybrid Cars: a History, North Carolina: McFarland & Company, p. 121, ISBN 978-0-7864-1872-9

- ↑ Toshiba's New Rechargeable Lithium-Ion Battery Recharges in Only One Minute (press release), Toshiba, 29 March 2005, http://www.toshiba.co.jp/about/press/2005_03/pr2901.htm, retrieved 2009-04-25

- ↑ Lakeman, Geoffrey (16 August 2007), The electric car that's faster than a Ferrari, Daily Mirror, http://www.mirror.co.uk/news/top-stories/2007/08/16/the-electric-car-that-s-faster-than-a-ferrari-115875-19638821/, retrieved 2009-04-25

- ↑ NanoSafe, Lightning Car Company, http://www.lightningcarcompany.co.uk/nanosafe.php, retrieved 2009-04-25

- ↑ New quick charger for electric cars is really quick, 5 July 2010, http://www.crunchgear.com/2010/07/05/new-quick-charger-for-electric-cars-is-really-quick/

- ↑ Park and Ride Locations, Calgary Transit, 16 April 2009, http://www.calgarytransit.com/html/park_n_ride_locations.html, retrieved 2009-04-25

- ↑ Ian Clifford, CEO of ZENN Motors, in Discovery Channel's Green Wheels episode 1

- ↑ Mitchell, T. (2003) (PDF), AC Propulsion Debuts tzero with LiIon Battery (press release), AC Propulsion, archived from the original on 2007-06-09, http://web.archive.org/web/20070609122616/http://www.acpropulsion.com/LiIon_tzero_release.pdf, retrieved 2009-04-25

- ↑ Lienert, Dan (21 October 2003), The World's Fastest Electric Car, Forbes, http://www.forbes.com/2003/10/21/cx_dl_1021vow.html, retrieved 2009-09-21

- ↑ "www.review-electric-car.com". www.review-electric-car.com. http://www.review-electric-car.com/motorshows/frankfurtshow2009.html. Retrieved 2010-07-16.

- ↑ BIT Attends the Delivery Ceremony of the 2008 Olympic Games Alternative Fuel Vehicles, Beijing Institute of Technology, 18 July 2008, http://english.bit.edu.cn/col399/article.htm1?id=25756, retrieved 2009-07-13

- ↑ Knipe, Thomas J.; Gaillac, Loïc; Argueta, Juan (10 September 2003) (PDF), 100,000-Mile Evaluation of the Toyota RAV4 EV, Southern California Edison, Electric Vehicle Technical Center, http://www.evchargernews.com/miscfiles/sce-rav4ev-100k.pdf, retrieved 2009-04-27

- ↑ "Tesla Motors Moving Quickly to Commercialization of an Electric Car". GreenCar Magazine. 2009-07-09. http://www.greencarmagazine.net/2009/07/tesla-motors-moving-quickly-to-commercialization-of-an-electric-car/. Retrieved 2009-08-01.

- ↑ Tesla Motors (2008-09-09). "Tesla Motors Selects BorgWarner for Production of New Gearbox for Tesla Roadster". Tesla Motors. http://www.teslamotors.com/media/press_room.php?id=968.

- ↑ O'CONNELL, VP TESLA MOTORS, DIARMUID, DAN NEIL, and Dan Rather, hosts. "Electric Cars." DAN RATHER REPORTS GLOBAL CORRESPONDENT . CQ-Roll Call Group. 9 Sept. 2009. Gale Virtual Reference Library. Web. Transcript. 5 Oct. 2009.

- ↑ "Lithium Carbonate Supplies Abound! – Sequence Omega". Sequence-omega.net. http://www.sequence-omega.net/2009/05/15/lithium-carbonate-supplies-abound/. Retrieved 2010-07-16.

- ↑ Voelcker, John (January 2007), "Lithium Batteries for Hybrid Cars", IEEE Spectrum (IEEE), http://spectrum.ieee.org/jan07/4848, retrieved 2009-04-27

- ↑ Hively, Will (August 1996), "Reinventing the wheel - A flywheel may be the key to a car that's both powerful and efficient", Discover, http://discovermagazine.com/1996/aug/reinventingthewh842, retrieved 2009-04-24

- ↑ Schindall, Joel (November 2007), [http://spectrum.ieee.org/green-tech/advanced-cars/the-charge-of-the-ultra-capacitors "The Charge of the Ultra - Capacitors Nanotechnology takes energy storage beyond batteries"], IEEE Spectrum, http://spectrum.ieee.org/green-tech/advanced-cars/the-charge-of-the-ultra-capacitors, retrieved 2010-08-12

- ↑ Ehrlich, David (31 March 2008), Zenn gearing up for EEStor-powered car, Cleantech Group, http://media.cleantech.com/2644/zenn-gearing-up-for-eestor-powered-car, retrieved 2009-04-27

- ↑ Dalloul, Motasem (29 May 2008), Gaza Cars From Cooking Oil to Batteries, IslamOnline, http://www.islamonline.net/servlet/Satellite?c=Article_C&cid=1209358045722&pagename=Zone-English-News/NWELayout, retrieved 2009-04-27

- ↑ Stephanov, Rostik, ed. (21 August 2008), Gaza Engineers Offer Alternative To Gaza Fuel Crisis, infolive.tv, http://www.infolive.tv/en/infolive.tv-22806-israelnews-gaza-engineers-offer-alternative-gaza-fuel-crisis, retrieved 2009-04-27

- ↑ (in Japanese and English mixed) Video at eliica.com, Eliica, http://www.eliica.com

- ↑ "Notice 2009-89: New Qualified Plug-in Electric Drive Motor Vehicle Credit". Internal Revenue Service. 2009-11-30. http://www.irs.gov/irb/2009-48_IRB/ar09.html. Retrieved 2010-04-01.

- ↑ "State and Federal Incentives for EVs, PHEVs and Charge Stations". Plug In America. http://action.pluginamerica.org/t/5960/content.jsp?content_KEY=5545. Retrieved 2010-05-29.

- ↑ Paul Hudson (2010-02-28). "£5,000 grant to buy plug-in electric cars". The Daily Telegraph. http://www.telegraph.co.uk/motoring/green-motoring/7316351/5000-grant-to-buy-plug-in-electric-cars.html. Retrieved 2010-04-23.

- ↑ "Ultra-low carbon cars: Next steps on delivering the £250 million consumer incentive programme for electric and plug-in hybrid cars". Department for Transport. July 2009. http://www.dft.gov.uk/adobepdf/163944/ulcc.pdf. Retrieved 2010-04-23.

- ↑ "Growing Number of EU Countries Levying CO2 Taxes on Cars and Incentivizing Plug-ins". Green Car Congress. 2010-04-21. http://www.greencarcongress.com/2010/04/acea-tax-20100421.html#more. Retrieved 2010-04-23.

- ↑ "An Increasing Number of Member States Levy CO2-Based Taxation or Incentivise Electric Vehicles". European Automobile Manufacturers Association. 2010-04-21. http://www.acea.be/index.php/news/news_detail/an_increasing_number_of_member_states_levy_co2_based_taxation_or_incentivis/. Retrieved 2010-04-23.

External links

Organizations

- Open Source Electric Car by Society for Sustainable Mobility

- US Electric Auto Association (EAA) and recharging points

- Electric Car Society founded in 1982

- Electrification Coalition (business alliance)

|

||||||||||||||||||||||||||

.jpg)